-

-

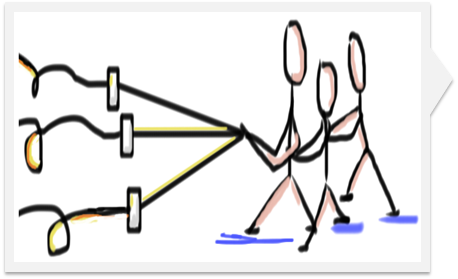

FDMGlobalSolutions provides services for your company, like support, process optimization and training.

We consider a priority to avoid difficult situations instead to react correcting them in this case we save machine stops, wire scrap and the need to replace dies always with a high cost.

You can ask us to evaluate your process in order to prevent further problems or to control your die shop in order to have always the right dies ready for changes.

-

Support

-

We can provide both preventive and corrective support:

- Preventive actions: We analyse your process and we identify the points were you have a risk, making an estimation of the economic impact. We provide all needed information for the decision process.

- Corrective actions: wire breaks, die breaks, short die life… We can help you to improve them reducing the scrap, improving the die life and as an immediate result, improving the quality of the wire and reducing purchases of the different materials.

We always build the right system and indicators to make possible an easy follow up of improvements, in order to avoid in the future the same situation

-

Die Shop

-

We take care of your die shop, dies change, maintenance calendars, recuts, and management of your purchases if needed.

Long time ago was quite normal for all the companies to have a die expert that was in charge to manage the dies stock, the replacement calendar and to take care of the unexpected problems. Unfortunately right now only few companies have this role and this task is delegated to machine operators, who try to do his best but with a clear lack of knowledge.

FDMGlobalSolutions can do this job for you, we can ask one of our technical experts to do it in your factory periodically. If you already have this figure we can provide all the tools and support to do it always properly.

-

Training

-

From our point of view there are two ways to look at the training: One is the view that as a user of the ISO, TS or any standards we have to keep training for our people and we have to justify. The other view is that trainning our people they have more knowledge, they feel better, they feel more comfortable with his job and obviously they achieve better results and they feel more compromised with the job.

We train your people from the factory in order to use the tools always in the better way and your supervisors or directors in order to have all the info about the products they are using in their factories. Always a certificate is delivered.

We can do training seminars as part of periodical training, as a preventive action after a problem is solved or as part of your events or meetings as one more activity related to your professional activities.